Roller Bearings

Cylindrical Roller Bearings

Cylindrical roller bearings are available in many designs, dimension, series and sizes. The majority of these are bearings with cage(s), which can accommodate heavy radial loads and can operate at high speeds. The full complement bearings (without cage) can support particularly heavy radial loads, but because of the special kinematic conditions in these bearings, they cannot be operated at such high speeds as the caged bearings. Cylindrical roller bearings are also available in double or multi-row design.

Full Complement Roller Bearings

Full complement cylindrical roller bearings have solid inner and outer rings and rib-guided cylindrical rollers. Since these bearings have the largest possible number of rolling elements, they have extremely high radial load carrying capacity, high rigidity and are suitable for particularly compact designs. Due to their kinematic conditions, however, they cannot achieve the high speeds that are possible when using cylindrical roller bearings with cage.

Full complement cylindrical roller bearings are available as non-locating, semi-locating and locating bearings and in single and double row designs.

Double Row Roller Bearings

Double row cylindrical roller bearings have a low cross section, high load carrying capacity and high stiffness. Therefore they are mainly used in machine tools, rolling mill stands, grinding mills and also large gearboxes.

The bearings are separable, i.e. the ring with integral flanges together with the roller and cage assemblies can be mounted separately from the other bearing ring or all bearing components can be mounted separately. This facilitates the mounting, inspection and maintenance of these bearings.

Multi Row Roller Bearings

Multi-row cylindrical roller bearings are only able to accommodate radial loads. They are therefore mounted together with deep groove or angular contact ball bearings, or with tapered roller bearings, either radial or thrust designs, which take up the axial loads. The four-row and six-row cylindrical roller bearings are of separable design, i.e. the ring or rings with integral flanges and the roller and cage assemblies can be mounted independently of the free rings, or all bearing components can be mounted separately. This considerably simplifies bearing mounting, maintenance and inspection. A certain limited axial displacement of the shaft with respect to the housing can be accommodated within the bearing.

MAC four-row cylindrical roller bearings have a cylindrical bore and some sizes are also available with tapered bore. Bearings with tapered bore can be adjusted during mounting to give a certain radial internal clearance or a defined preload.

Spherical Roller Bearings

Spherical roller bearings have two rows of rollers, a common sphered outer ring raceway and two inner ring raceways inclined at an angle to the bearing axis The centre point of the sphere in the outer ring raceway is at the bearing axis. Therefore, the bearings are self-aligning and insensitive to misalignment of the shaft relative to the housing, which can be caused, for example, by shaft deflection. Spherical roller bearings are designed to accommodate heavy radial loads, as well as heavy axial loads in both directions.

Bearing performance is not only determined by load or speed ratings. There are a number of other factors that contribute to bearing performance. To a large extent, performance is influenced by the geometry of the rollers, raceways and cages, the heat treatment, as well as the surface finish of all contact surfaces.

Combined Roller Bearings

MAC offers Combined bearings and mating profiled rail steel sections, for heavy load application with the following features.

Combined Bearings with inner rings made from bearing steel En SAE 52100 and Outer Ring made from cast hardened steel uUNI 16 Cr Ni 4.

Combined Bearings are hardened and can take very high axial loads.

These lubricated bearings can be easily removed and re-lubricated.

Profiles are made of high quality steel in UNIFE 510.C with maximum length of 12000MM.

Combined bearings can be easily supplied with profiles and flanges duly welded free of cost.

These bearings find application in the field of Material handling, packaging machines, mining equipment, steel mill, forklift, transport and conveyor system, EOT Cranes, etc.

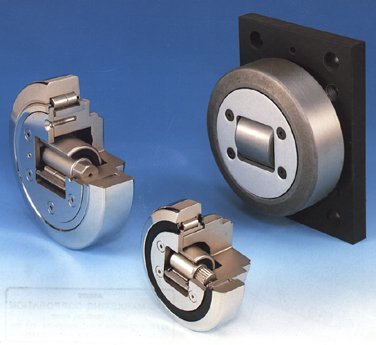

CAM follower/Track Roller Bearings

The Camrol and Cam Follower bearings offered by MAC Marketing are designed and built specifically to withstand intermittent shock and heavy load of cam operation. Full type needle roller bearing construction gives them ultimate in radial capacity, improving load-carrying qualities. A soft stud stem adds toughness and permits reworking for slight dimensional changes. Holes through either side or ends of the stud provide for convenient re-lubrication. Both zone and through -hardening are used to provide the right combination of hardness for maximum life. These bearings are available with or without seals in inch as well as in metric dimensions, in normal and heavy-duty types, including in stainless steel materials for applications in industries like machine tools, aerospace, printing machinery and material handling equipment, etc

Track runner bearings are designed to run on all types of tracks and to be used in cam drives, conveyor systems, etc. These bearings have a thick-walled outer ring, which enables them to accommodate high radial loads, while reducing distortion and bending stresses.

Thrust Roller Bearings

Cylindrical roller thrust bearings are suitable for arrangements which can support heavy axial loads. Furthermore, they do not suffer from shock loads, are stiff and require little axial space. They are single direction bearings and can only accommodate axial loads in one direction. Cylindrical Thrust roller bearings are simple in design and generally consist of shaft washer, a housing washer and one or more cylindrical roller and cage axial assembly.

MAC Marketing supplies various types of Thrust Bearings both and Ball and Roller Type and also Thrust slide Bearings. the class of precision for these bearings ranging from P’0′ to P’4′ and a lot which can be supplied upon special requests.

Sizes ranging from 20mm ID upto 1500mm. These bearings find excellent application such Machine Tools, Construction equipment, linkages and chains to name a few. The slide thrust bearings can be supplied in miniature size and each size from standard to customers design both self lubricating and maintenance free option, there by giving an edge of technology over other manufacturers. Thrust roller can be supplied from standard to custom sizes.