Power Transmission Products, Coupling, Backstops, Free Wheel Clutches, Chains

Coupling

MAC offers the various types of Cross+Morse flexible shaft couplings which can cater for the requirements of most types of drive installation. A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded.

The primary purpose of couplings is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement or both. By careful selection, installation and maintenance of couplings, substantial savings can be made in reduced maintenance costs and downtime.

Backstops

Backstop clutches incorporate a standard FND 400 complete unit clutch that allows rotation of a mechanism, in one direction only, while the connected momentum lever stops motion past the ground location. These backstop designs are used for backstopping (or holdback) applications, and to prevent any rotation in the reverse direction at all times. Although the clutch normally overruns, it is referred to as a holdback or backstop. The main applications that use backstop clutches are conveyors, gear reducers and similar equipment.

Free Wheel Clutches

In mechanical or automotive engineering, a freewheel or overrunning clutch is a device in a transmission that disengages the driveshaft from the driven shaft when the driven shaft rotates faster than the driveshaft. An overdrive is sometimes mistakenly called a freewheel, but is otherwise unrelated.

The condition of a driven shaft spinning faster than its driveshaft exists in most bicycles when the rider holds his or her feet still, no longer pushing the pedals. In a fixed-gear bicycle, without a freewheel, the rear wheel would drive the pedals around.

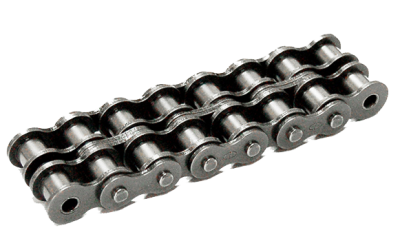

Chains

A chain is a series of connected links which are typically made of metal. A chain may consist of two or more links.

Those designed for lifting, such as when used with a hoist; for pulling; or for securing, such as with a bicycle lock, have links that are torus shaped, which make the chain flexible in two dimensions (The fixed third dimension being a chain’s length.)

Those designed for transferring power in machines have links designed to mesh with the teeth of the sprockets of the machine, and are flexible in only one dimension. They are known as roller chains, though there are also non-roller chains such as block chain.