Wire Race Bearings

Background

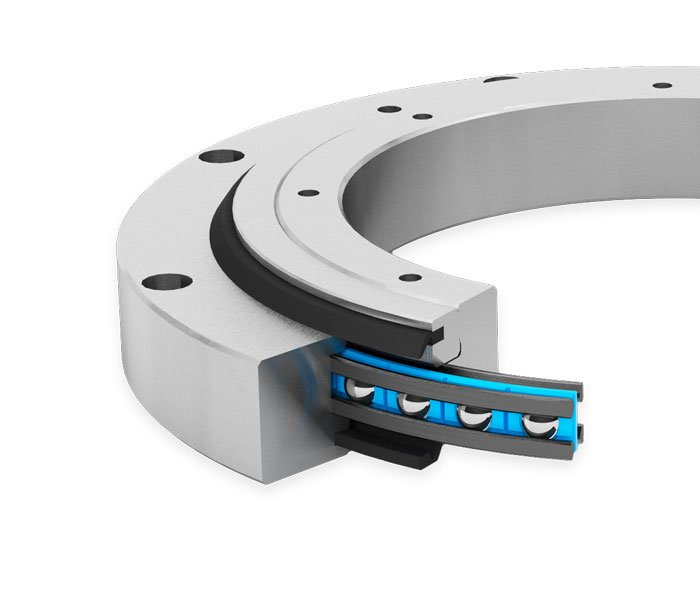

A wire race bearing is a four-point angular contact ball bearing. It consists of four wires which are formed into a circle to fit a housing groove machined into the inner and outer diameters of the relatively stationary and rotating parts. Into each of the wires is produced an accurately profiled groove which provides the bearing track upon which the balls run.

These balls are separated by a continuous cage band and thus the load is evenly carried. This cage band prevents any friction between the balls and aids lubrication. As it is the bearing elements that carry the load the role of the housing is merely to hold the bearing assembly together. That is the choice of housing material does not affect the strength of the bearing. The housing can be made from steel, cast iron or aluminium alloys. The wire races are made from silicon chrome hardened and tempered wire with a minimum sectional hardness of 52 HRC.

The wires are supplied with an accurate gap to allow for differential expansion (between the wires and the housings) over a wide temperature range typically 240 – 390 K. Owing to this gap the wires fit the housing exactly which eliminates machine tolerances.

The picture to the right shows a typical 3-part housing which is suitable to carry both radial and axial loads in nearly equal proportions. The cross section in this case is uniform and thus has a contact angle of 45 degrees. This angle can be reduced to form a rectangular cross section and thus change the load carrying characteristics for example to sustain more axial and less radial loads.

Sample Diagram of Typical 3 part-housing

Thrust Bearings

Figure 1: altered support housing

By altering the support housing design, MAC can offer a bearing more suited to carrying axial loads as shown in figure 1.

Alternatively, a double row of axial bearings can carry even higher axial loads, for example in indexing turntables.

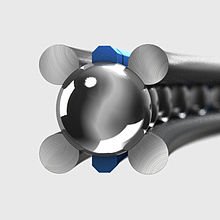

Figure 2: round profile races

In applications where the loads are low, round profile races can be installed as shown in figure 2.

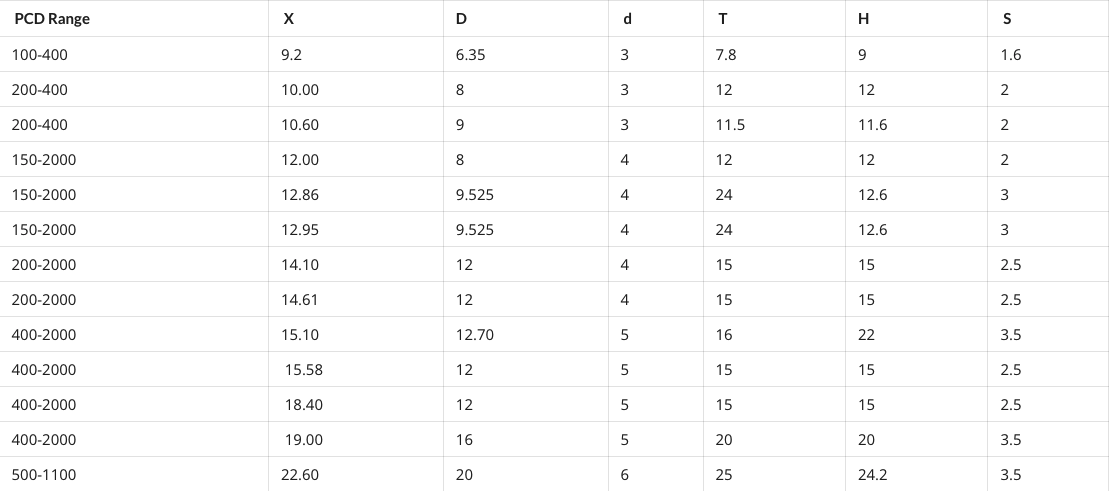

Table of Dimensions and Accompanying Diagrams

All measurements are in millimeters (mm)

Seals

To prevent dirt and other contaminants from entering the bearing and to retain the lubricant, a variety of seals can be fitted. Example below.

Corrosion Proof Bearings

MAC can also offer a limited range of stainless steel bearings from the above range for a low maintenance solution.

The above Wire Race bearings offered by MAC are manufactured by Healy Bearing International Limited, England.

Applications

Many of the world’s leading circular knitting machine manufacturers now use Healy wire race bearings. They help to reduce power consumption, generate less frictional heat and need a much lower starting torque than conventional face to face designs.

Typical cross-section through a circular knitting machine demonstrating how the wire race housing is incorporated into the machine design.

Wire race bearings can be used in many diverse applications, such as

Robotic Arms

Military applications

Rotary tables & indexing bases

Fork lift trucks

Circular knitting machine

Carding & yarn preparation machinery